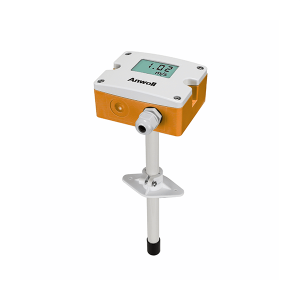

MST23 Monocrystalline silicon differential pressure transmitter

utilizes a MEMS-based monocrystalline silicon sensor combined with a welded liquid-level flange and silicone-oil filling to isolate the sensing element from the process medium—preventing crystallization, solidification, vaporization, condensation or fractionation in the impulse line. It measures differential pressure, liquid level, flow and density of liquids, gases or steam, then outputs a stable 4–20 mA DC signal (with optional HART or RS485) without interruption during configuration.

Key Specifications:

• Core Function: High-accuracy differential pressure/level/density measurement (liquid/gas/steam)

• Sensor Technology: MEMS monocrystalline silicon diaphragm with welded flange and silicone-oil filling

• Output Signal: 4–20 mA DC two-wire; optional 4–20 mA+HART; RS485 four-wire

• Operation: Local LCD & three-button control; remote configuration via communicator/software/mobile app

• Flange Isolation: Prevents medium effects (crystallization, vaporization, etc.) on sensor

• Accuracy: ±0.2 % FS (turn-down ≤ 10 : 1); ±0.02 % × TD (10 < TD ≤ 100 : 1)

• Measuring Range: –100 kPa…0.3 MPa up to 0…60 MPa; turndown ratio up to 100 : 1

• Response Time: ≤ 0.2 s sensor; 0–60 s electronic damping; ≤ 5 s start-up; ≤ 2 s recovery

• Environmental Ratings: Ambient –20…+70 °C (with display) / –40…+85 °C; medium up to +120 °C; IP65; Ex d II CT6

• Process & Flange Connections: G1/4, G1/2, NPT1/4, M20×1.5; flange standards DIN PN / ANSI; sizes DN 50/80/100…

• Materials: 316L SS diaphragm (optional Hastelloy C, Tantalum); silicone oil (normal or high-temperature)

• Power & Load: 12–36 V DC; RS485 comms load 250–600 Ω

Typical Applications:

✔ Liquid/gas/steam level and density monitoring

✔ Differential pressure measurement in HVAC, filter-clog detection & pump protection

✔ Flow and interface measurement in chemical, water-treatment & petrochemical processes

✔ Industrial process control (power plants, food & beverage, pharmaceuticals)

✔ High-temperature/pressure environments in marine, automotive & aerospace systems

Catalogue:

This pressure transmitter is used to measure the liquid level of liquids, gases, or vapors. Flow rate and pressure are then converted into 4-20mA DC signal output.

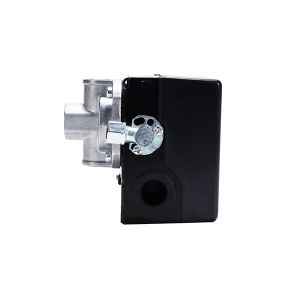

Related Products

Additional information

| Medium | gas, liquid |

|---|---|

| Diaphragm material | 316L, Hastelloy C, Tantalum, Other |

| Range | 6 kPa, 40 kPa, 250 kPa, 1 MPa, 3 MPa |

| Accuracy | ± 0.075%F.S |

| Electrical interface | M20*1.5 waterproof lead-out, NPT1/2 waterproof lead-out |

| Flange size | DN50, DN80, DN100 (2 inches, 3 inches, 4 inches) |

| Temperature (Working) | -20…+70℃ [-4…+158℉] with display |

| Temperature (Storage) | -40…+85°C [-40…+185℉] |

| IP grade | IP65 |

utilizes a MEMS-based monocrystalline silicon sensor combined with a welded liquid-level flange and silicone-oil filling to isolate the sensing element from the process medium—preventing crystallization, solidification, vaporization, condensation or fractionation in the impulse line. It measures differential pressure, liquid level, flow and density of liquids, gases or steam, then outputs a stable 4–20 mA DC signal (with optional HART or RS485) without interruption during configuration.

Key Specifications:

• Core Function: High-accuracy differential pressure/level/density measurement (liquid/gas/steam)

• Sensor Technology: MEMS monocrystalline silicon diaphragm with welded flange and silicone-oil filling

• Output Signal: 4–20 mA DC two-wire; optional 4–20 mA+HART; RS485 four-wire

• Operation: Local LCD & three-button control; remote configuration via communicator/software/mobile app

• Flange Isolation: Prevents medium effects (crystallization, vaporization, etc.) on sensor

• Accuracy: ±0.2 % FS (turn-down ≤ 10 : 1); ±0.02 % × TD (10 < TD ≤ 100 : 1)

• Measuring Range: –100 kPa…0.3 MPa up to 0…60 MPa; turndown ratio up to 100 : 1

• Response Time: ≤ 0.2 s sensor; 0–60 s electronic damping; ≤ 5 s start-up; ≤ 2 s recovery

• Environmental Ratings: Ambient –20…+70 °C (with display) / –40…+85 °C; medium up to +120 °C; IP65; Ex d II CT6

• Process & Flange Connections: G1/4, G1/2, NPT1/4, M20×1.5; flange standards DIN PN / ANSI; sizes DN 50/80/100…

• Materials: 316L SS diaphragm (optional Hastelloy C, Tantalum); silicone oil (normal or high-temperature)

• Power & Load: 12–36 V DC; RS485 comms load 250–600 Ω

Typical Applications:

✔ Liquid/gas/steam level and density monitoring

✔ Differential pressure measurement in HVAC, filter-clog detection & pump protection

✔ Flow and interface measurement in chemical, water-treatment & petrochemical processes

✔ Industrial process control (power plants, food & beverage, pharmaceuticals)

✔ High-temperature/pressure environments in marine, automotive & aerospace systems

Catalogue:

This pressure transmitter is used to measure the liquid level of liquids, gases, or vapors. Flow rate and pressure are then converted into 4-20mA DC signal output.

This pressure transmitter is used to measure the liquid level of liquids, gases, or vapors. Flow rate and pressure are then converted into 4-20mA DC signal output.