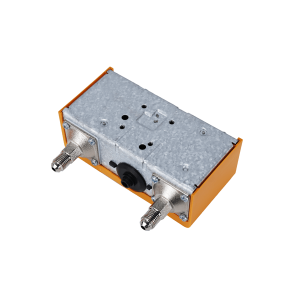

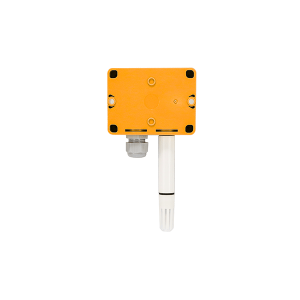

MST21 Monocrystalline silicon pressure transmitter

MST21 Monocrystalline Silicon Pressure Transmitter utilizes a high-precision MEMS sensor with a single-crystal silicon diaphragm to ensure excellent linearity, long-term stability, and fast dynamic response. It supports a wide turndown ratio (up to 100:1) and features a local display and control interface with reversible backlit LCD, making it highly adaptable for various measurement environments. The transmitter outputs a 4–20 mA signal (with optional HART or RS485), and supports full configuration via local buttons, remote communicator, software, or mobile app without disturbing the output signal.

Key Specifications:

• Core Function: High-accuracy pressure/level/density measurement for liquids, gases, and steam

• Sensor Technology: MEMS-based monocrystalline silicon diaphragm; ±0.075%FS accuracy

• Output Signal: 4–20 mA DC (isolated from configuration), optional HART or RS485

• Operation: Local three-button control or remote setup via software/communicator/mobile app

• Display: Reversible backlit LCD; local zero/full span adjustment

• Turn Down Ratio: Up to 100:1

• Response Time: ≤0.2 s sensor damping; configurable electronic damping 0–60 s

• Environmental Ratings:

– Ambient: –40 to +85 °C

– Medium: –20 to +70 °C (with display)

– Protection: IP65; explosion-proof version ExdIICT6 available

• Electrical Options:

– Supply: 12–36 VDC

– Alarm Modes: High (20.8 mA), Low (3.8 mA), Hold

• Process Connections: M20×1.5, G1/2, NPT1/2, others available

• Diaphragm Materials: 316L, Hastelloy C, Tantalum

• Range Options: From 200 Pa to 10 MPa, including gauge and absolute pressure types

• Stability: Annual drift ≤ ±0.2%FS

• Installation: Any orientation, max zero offset 400 Pa (correctable)

Typical Applications:

✔ Liquid/gas/steam level and density monitoring in tanks or pipelines

✔ Industrial process control (petrochemical, power generation, food & beverage)

✔ HVAC system differential and static pressure monitoring

✔ Pressure/level monitoring in pharmaceutical and water treatment plants

✔ Marine and aerospace environments requiring compact high-accuracy sensors

Catalogue:

This pressure transmitter is widely used for pressure measurement in industrial sites such as petroleum, chemical, power, and hydrology.

Related Products

Additional information

| Medium | gas, liquid |

|---|---|

| Diaphragm material | 316L, Hastelloy C, Tantalum, Other |

| Range | 6 kPa, 40 kPa, 250 kPa, 1 MPa, 3 MPa, 10 MPa |

| Accuracy | ± 0.075%F.S |

| Electrical interface | M20*1.5 waterproof lead-out, NPT1/2 waterproof lead-out |

| Temperature (Working) | -20…+70℃ [-4…+158℉] with display |

| Temperature (Storage) | -40…+85°C [-40…+185°F] |

| IP grade | IP65 |

MST21 Monocrystalline Silicon Pressure Transmitter utilizes a high-precision MEMS sensor with a single-crystal silicon diaphragm to ensure excellent linearity, long-term stability, and fast dynamic response. It supports a wide turndown ratio (up to 100:1) and features a local display and control interface with reversible backlit LCD, making it highly adaptable for various measurement environments. The transmitter outputs a 4–20 mA signal (with optional HART or RS485), and supports full configuration via local buttons, remote communicator, software, or mobile app without disturbing the output signal.

Key Specifications:

• Core Function: High-accuracy pressure/level/density measurement for liquids, gases, and steam

• Sensor Technology: MEMS-based monocrystalline silicon diaphragm; ±0.075%FS accuracy

• Output Signal: 4–20 mA DC (isolated from configuration), optional HART or RS485

• Operation: Local three-button control or remote setup via software/communicator/mobile app

• Display: Reversible backlit LCD; local zero/full span adjustment

• Turn Down Ratio: Up to 100:1

• Response Time: ≤0.2 s sensor damping; configurable electronic damping 0–60 s

• Environmental Ratings:

– Ambient: –40 to +85 °C

– Medium: –20 to +70 °C (with display)

– Protection: IP65; explosion-proof version ExdIICT6 available

• Electrical Options:

– Supply: 12–36 VDC

– Alarm Modes: High (20.8 mA), Low (3.8 mA), Hold

• Process Connections: M20×1.5, G1/2, NPT1/2, others available

• Diaphragm Materials: 316L, Hastelloy C, Tantalum

• Range Options: From 200 Pa to 10 MPa, including gauge and absolute pressure types

• Stability: Annual drift ≤ ±0.2%FS

• Installation: Any orientation, max zero offset 400 Pa (correctable)

Typical Applications:

✔ Liquid/gas/steam level and density monitoring in tanks or pipelines

✔ Industrial process control (petrochemical, power generation, food & beverage)

✔ HVAC system differential and static pressure monitoring

✔ Pressure/level monitoring in pharmaceutical and water treatment plants

✔ Marine and aerospace environments requiring compact high-accuracy sensors

Catalogue:

This pressure transmitter is widely used for pressure measurement in industrial sites such as petroleum, chemical, power, and hydrology.

This pressure transmitter is widely used for pressure measurement in industrial sites such as petroleum, chemical, power, and hydrology.