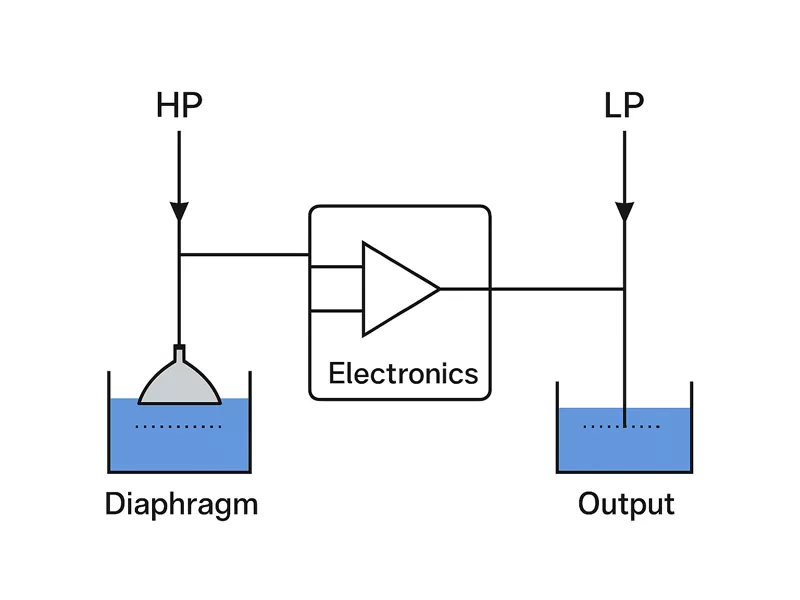

A differential pressure transmitter measures the pressure difference between two points. Process pressures are applied to a sensing element (such as a diaphragm) from the high-pressure side (HP) and low-pressure side (LP). The resulting differential pressure causes diaphragm deflection, which is converted into an electrical signal by strain gauges or capacitive sensors. Electronics process this signal and output a standardized current or digital signal for monitoring flow, level, or filter conditions in industrial systems.