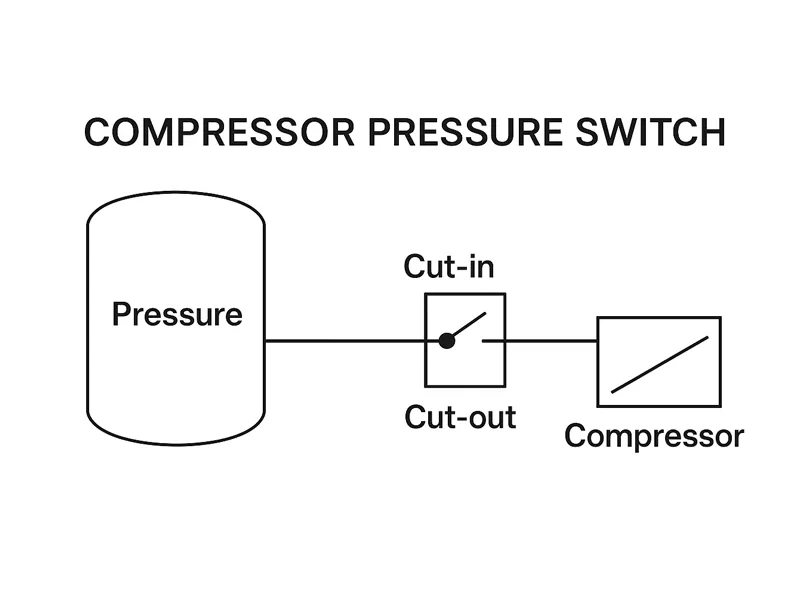

A Compressor Pressure Switch monitors the air pressure within the compressor’s receiver tank. When the pressure drops below a preset cut-in point, the switch closes its electrical contacts, activating the compressor motor. As pressure rises and reaches the cut-out point, the switch opens the contacts, stopping the compressor. This automatic control maintains the desired pressure range, prevents over-pressurization, and reduces energy waste. The switch is essential for protecting the compressor, improving safety, and ensuring consistent air supply in pneumatic systems.